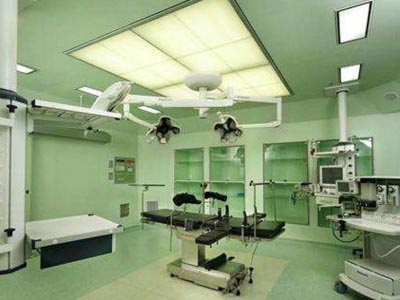

Interiors

Surgical site infections (SSIs) are the second to the most common site of health care associated infections (HAIs). These complications of surgical procedures cause considerable morbidity and, when these occur deep at the site of the procedure, can carry mortality as high as 77%. There are several key steps or “chains” that have to be connected to result in infection. However, for SS is the initial introduction of microbial pathogens occurs most often during the surgical procedure performed in the Operating Theatre (OT). Thus to reduce the risk of SSI, a systematic but realistic approach must be applied with the awareness that this risk is influenced by characteristics of the patient, operation, personnel and health care facility, Following the path towards putting all essential benefits in an Operation Theatre new sphere rises which now is called with ” Modular Operation Theatre.”

Air and light integrated Plan-air confirms to class 100 Certified Performance to DIN 4799 and ISO 14644. Plan-Air Ceiling system with unidirectional airflow. Plenum unit, Holding structure & Top plenum are made of 1.6mm thick Aluminum Sheet, with aluminum extrusion frame & sealed gasket conforming to DIN 4799 standards for the air distribution system with HEPA filter having efficiency 99.97% down to 0.3 micron.

Hermetically sealing doors are available in both Sliding and none Sliding type of doors with option for manual or automated operation (applicable only with Hermetically sealing doors), automation employs for door with the help Microprocessor based Electronic Control Unit for controlling movement with low noise level motor. The acceleration and speed of the door can be adjusted. These Doors comes with a special inside & outside lever handle that lifts out the door blade from its hermetic closing position, thus allowing effortlessly open / closing manual operation of these heavy doors, for smooth & effortless sliding, the door is having special nylon top rollers with double roller bearings. The system comes complete with Elbow switch/foot (optional) switch & radar switch (touch less sensor) for operation of Door, with glass vision window & necessary accessories etc. The automation controller for the door is microprocessor base with regulated electro-mechanical sliding door drive and the automation is having the capacity to operate a door with weight of 250 kg & maximum door with of P 3500mm. The Automation of Door carries the variable/adjustable opening and closing speeds, with opening speed adjustable between 120mm / sec – 800mm / sec and the closing speed adjustable between 120mm / sec –500mm / sec.

Scrub Station is designed for use in operation theatre complex, providing surgeons with a convenient sink for pre-op scrub up. The Scrub Station is made out from heavy gauge high class SS304 stainless steel sheet of 1.6mm thickness and seamless welded with brush up finish having optimum finishing quality up to hair line finishing touch.

The Scrub Station comes along & equipped with front access panel, which is easily removed for access to the water control valve, waste connections, stoppers & strainers, for hands free operation it equipped with infrared sensor with built in range of adjustment & knee/foot operated functions with thermostatic mixing valve control is provided behind the access panel to maintain water temperature. The Scrub Sink is having pre defined settings of 1,3, 6,10 minutes as per user requirements, which make it very convenient to operate as of having user friendly functioning.

Support Accessories

- Surgicals Scrub Sink

- X-Ray Viewing Screens (Twin Plates)

- Operation Theatre Control Panel (Digital)

- Pressure Relief Damper (PRD)

- Operating List – Writing Board

- Equipment Storage Unit

- Hatch Box

- Peripheral Lights

- Moveable Pendant – Double Arm

- Moveable Pendant – Single Arm

- Swill Pendant

Driver Cabin

- Improved Health & Safety- Due to the site element of modular construction, HMS can provide much safer working environments when compared with traditional construction methods.

- Minimal Site Disruption- Thanks to the Pre Fabricated Modular Operation Theatre construction method there is far less disruption and noise to the surrounding area in comparison with traditional methods of Operation Theatre construction.

- No Compromise On Quality- With the HMS Modular Operating System, one will experience none of the compromises normally associated with Modular construction such as “bouncy floors, Cavities, Sharp Edges” etc. and client can achieve the International Quality Modular Operation Theatre here in India with in nominal expenses.

- Highly Customizable- HMS Modular System is highly customizable ensuring the end user has no restrictions regarding layout, internal appearance and external treatments.

- Sustainability- Modular Operation Theatres are more energy efficient, environmentally friendly and delivering a rust and maintenance free system in most environments for many years.

- HMS Modular Operation Theatre System is based on International Healthcare / Medical Solutions- We are committed to sourcing our materials from across the globe helping to reduce project costs, our carbon footprint and helping the economy.